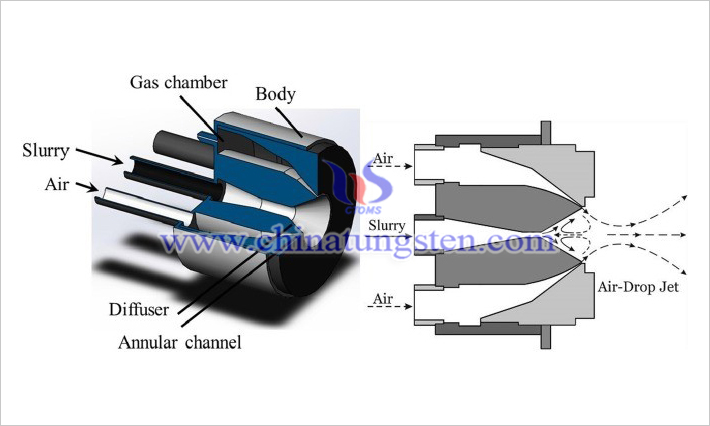

Coal water slurry is a new type of coal based liquid fuel rising in the 1970s. It is mainly composed of 65% coal, 34% water and 1% chemical additives. Compared with other types of fuels, it has many advantages, such as low sulfur content, high combustion efficiency, SO2, NOx and other pollutant emissions are lower than ordinary oil and coal. It is widely used in power station boilers, industrial boilers and industrial kilns to replace oil, gas and coal. It is an important part of today's clean coal technology. Cemented carbide nozzle is widely used in coal water slurry burner. It makes coal water slurry fuel burn more fully and effectively through good fuel atomization. According to the properties of fuel and the requirements for atomization quality, cemented carbide nozzle can also be divided into pneumatic type, mechanical type, rotating cup type and ultrasonic type. The rationality of its structure determines the atomization effect of coal water slurry, and the anti-wear and thermal shock properties of its materials determine the service life of the nozzle, and directly affect the economy and safety of coal water slurry application.

Typical Tungsten Cemented Carbide Threaded Internal Hexagonal Nozzle

Tungsten Cemented Carbide Coal Water Slurry Nozzle (sciencedirect.com)

When the coal water slurry nozzle works, it mainly bears the low angle erosion of coal water slurry, and the wear mechanism is mainly plastic deformation and micro cutting. The wear of cemented carbide coal water slurry nozzle mainly includes grain shedding, brittle fracture and grinding damage, and the higher the CO content in cemented carbide, the greater the erosion wear rate. Therefore, it should be made of less CO content or without high hardness bonded phase alloy or direct powder metallurgy. Compared with coal water slurry nozzle made of other metal materials, cemented carbide nozzle has better wear resistance and corrosion resistance and longer service life. However, cemented carbide itself is brittle, its hardness, toughness and thermal shock resistance are lower than other metal materials, so it is not easy to process and is not suitable for making nozzles with complex shape and structure. Cemented carbide nozzle can improve its wear resistance and corrosion resistance by inlaying cemented carbide on the most easily worn parts.

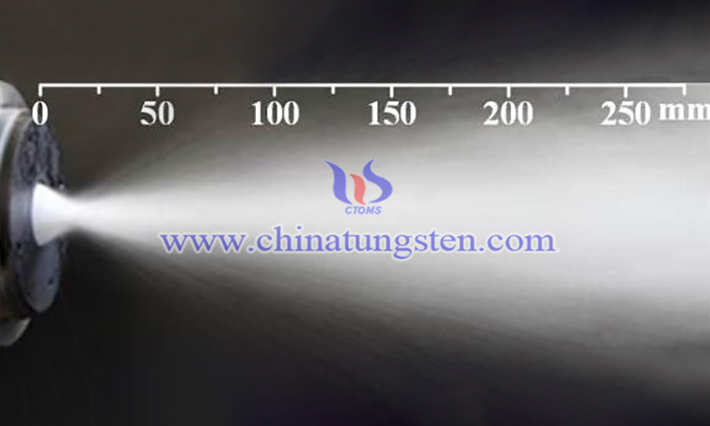

Gas-droplet flow generated by a pneumatic nozzle for coal-water slurry.Igor Anufriev, Institute of Thermophysics, Novosibirsk

Chinatungsten Online is the professional designer & producer of Tungsten and Molybdenum whether standard or customized. Tell us what you need, and we guarantee to deliver high-quality products and services in time. Any inquires or more details, please visit h5.chinatungsten.com or contact by email: sales@chinatungsten.com.