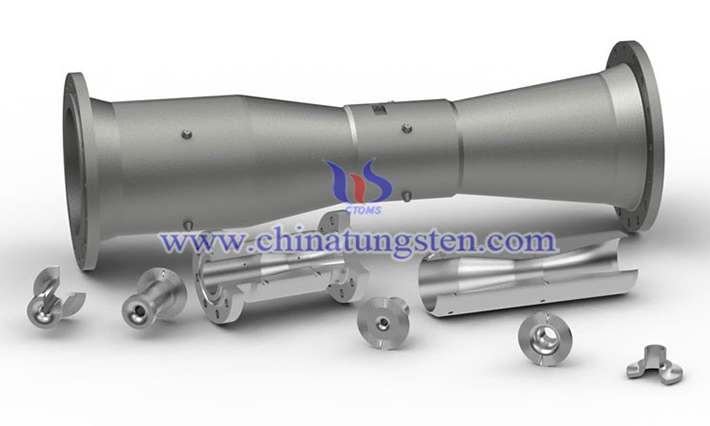

According to the classification of the shape of the nozzle hole, the shape of the cemented carbide nozzle hole determines its air flow mode. The nozzle generally has a straight hole or limiting hole and a Venturi hole.

1. Straight Hole Cemented carbide nozzle

The straight hole nozzle forms a sealed air flow mode for the on-site or internal air flow. This is conducive to the realization of small-scale work, such as cleaning parts, weld forming, cleaning handrails, steps, lattices, or stone carvings and other materials.

Tungsten Cemented Carbide Straight Hole Nozzle

2. Long Venturi Tungsten Cemented Carbide Nozzle

Generally speaking, the shape of the design hole of cemented carbide nozzle is determined by the air flow mode. Cemented carbide nozzle generally has two shapes: straight hole and Venturi hole. The straight hole nozzle designed by cemented carbide nozzle is a sealed air flow mode formed by internal air flow or air flow field. This will be more conducive to the completion of small work, and will be used to clean handrails, lattices, steps, cleaning parts, weld forming or stone carving. The mound hole nozzle forms a sufficient air flow mode, and the grinding speed is increased by up to 100% for a given pressure. Venturi nozzle is the best choice to improve productivity on the surface with large air flow. Compared with the straight hole nozzle, the long hill nozzle can increase the productivity by 40% when the abrasive consumption is about 40%.

3. Double Venturi Tungsten Cemented Carbide Nozzle

Double Venturi and wide throat nozzle are enhanced versions of long venturi nozzle. The double mound style can be considered as a nozzle with two nozzles between a set of cracks and holes to allow the incoming atmosphere to enter the downstream section. The outlet end is also wider than the traditional nozzle. These two modifications are made to increase the size of the airflow pattern and minimize the speed of abrasive loss.

Tungsten Cemented Carbide Venturi Nozzle

4. Wide Throat Tungsten Cemented Carbide Nozzle

The wide throat nozzle is equipped with a large outlet and a large divergent outlet. When matched with hoses of the same size, they can increase productivity by 15% over a smaller throat nozzle. When wide throat nozzles also have large divergent holes, they can adopt lower abrasive use mode under higher pressure, so that the yield can be as high as 60%.

For some lattice bridges, flange back and reduction points of pipe internal type, angled nozzles can be effectively used. Many operators spend a lot of time and abrasive to wait for a bounce to complete the work. Using an angled nozzle can always be repaired quickly as long as it takes less time, reducing the overall time.

Typical forms of Tungsten Cemented Carbide Nozzles

Chinatungsten Online is the professional designer & producer of Tungsten and Molybdenum whether standard or customized. Tell us what you need, and we guarantee to deliver high-quality products and services in time. Any inquires or more details, please visit h5.chinatungsten.com or contact by email: sales@chinatungsten.com.