On October 18th, the 2021 China (Shanghai) Tungsten Raw Material Industry Development High-end Forum was held as scheduled. And the Third Council of the Fourth Session of Cemented Carbide Branch of China Tungsten Industry Association(CTIA) and Cemented Carbide Industry Development Report Meeting was successfully held in Shanghai On the morning of the 19th. The meeting was hosted by Cemented Carbide Branch of CTIA, Zhuzhou Cemented Carbide Group, and the State Laboratory of Tungsten Cemented Carbide.

Ding Xuequan, President of China Tungsten Industry Association(CTIA)

At the meeting, the work report of the cemented carbide branch was reviewed, the list of companies joining the conference in 2021 were notified, the draft resolution for adjusting the directors was reviewed and approved, and the progress of the cemented carbide standard improvement work was reported. Ding Xuequan, President of CTIA, attended the meeting and delivered a speech. Xu Shangzhi, Director of Zhuzhou Cemented Carbide Group, delivered a speech on behalf of Chairman Mao Shanwen of Cemented Carbide Branch. Gao Zairong, general manager of Green Lifestyle (Hunan) Advanced Materials Co., Ltd., Jiang Tao, general manager of Xiamen Gold Egret Special Alloy Co.,Ltd, and Zhou Chongjian, general manager of Zigong Cemented Carbide Co., Ltd. attended the meeting as non-voting delegates. The third council of the fourth session was chaired by Yan Zhigang of Jiangxi Tungsten Cemented Carbide Co., Ltd., and the Cemented Carbide Industry Development Report was chaired by Zhang Zhongjian, the executive chairman of Zhuzhou Cemented Carbide Industry Association.

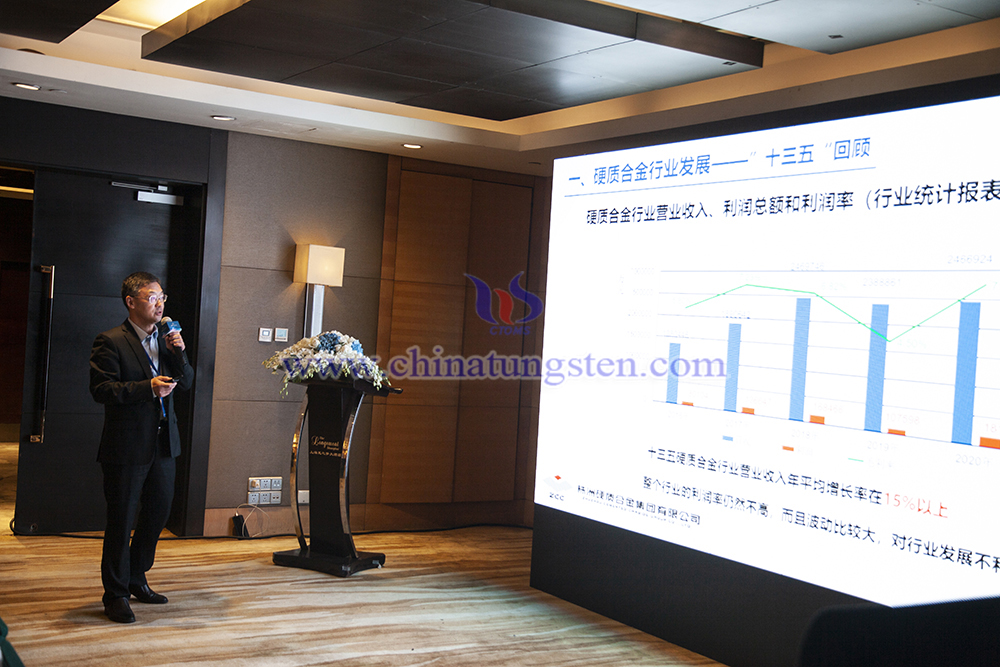

Xu Shangzhi, Director of Zhuzhou Cemented Carbide Group Co., Ltd.

Xu Shangzhi, Director of Zhuzhou Cemented Carbide Group Co., Ltd. gave a report "Review of the 13rd Five-year Plan of Cemented Carbide Industry and Development Trends of the 14th Five-year Plan". In addition to the statisics and overview of the development of China's cemented carbide industry during the 13rd Five-year Plan, the report focuses on the development of China's cemented carbide industry in new energy, Internet of Things(ITO), Intelligence manufacturing, Intelligence mining, driverless car, 5G construction, and new smelting. Technological requirements, infrastructure renewal and urban changes all have huge new demands and room for growth. At the same time, they have made a forward-looking discussion on the future technological development directions and trends of China's cemented carbide industry such as miniaturization, homogenization, and coating.

Zhou Peng, Senior Manager of the Planning Department of China Tungsten Hightech Materials Co., Ltd.

Zhou Peng, senior manager of the planning department of China Tungsten Hightech Materials Co., Ltd., made a report on "Analysis of Benchmarking Foreign Advanced Cemented Carbide Enterprises". According to the report, a comprehensive comparison between China's cemented carbide industry and Sandvik and Kennametal was carried out, and the respective market positioning, product portfolio, market characteristics, organizational form, sales model, competitive landscape, growth strategy, and risk management were compared. Data analysis has been carried out in various aspects; it has pointed out the outstanding market positioning and shortcomings of service capabilities of China's cemented carbide industry, low gross profit margin, narrow market positioning and other outstanding issues. It provides directions and suggestions for new product development and new technology applications in aerospace, transportation, general engineering and other industries.

Xie Yifeng, Chairman of the Board of Supervisors of China Tungsten Industry Association(CTIA)

Xie Yifeng, Chairman of the Board of Supervisors of CTIA, delivered a report "Ways of Recycling and Utilization of Tungsten Resources in China". The report makes a brief analysis of the current status of tungsten resources in China and the control of resources, prices, application markets and technology opening in western developed countries, and the current status and risks of resources in China, and compares and summarizes the recycling and utilization of materials in China and western developed countries. The status and problems of the recycling and utilization of soft materials such as alloys and metal tungsten hard materials, grinding or production process waste, and tungsten-containing catalyst wastes at home and abroad. The problems to be solved, the advantages and disadvantages of the chemical process, electrolysis process and zinc melting process are compared. The report focuses on China’s tungsten waste recycling industry planning, national policy support, technology research and development, and market application. And strategic forward thinking and suggestions.

Tang Aimin, Deputy General Manager of Zhuzhou Cemented Carbide Cutting Tools Co., Ltd.

Tang Aimin, deputy general manager of Zhuzhou Cemented Carbide Cutting Tools Co., Ltd., made a report on the "Development Status of Cemented Carbide Tools at Home and Abroad in the Post-epidemic Era". The report analyzes and discusses the impact of the epidemic on the cemented carbide industry from four aspects: macroeconomic analysis, cemented carbide tool market analysis, application industry situation analysis, key field tool technology development trends, and tool enterprise development paths Predict and analyze the development situation of its downstream application industry.

Hu Ming, Deputy Secretary-General of China Brazing Tools Association

Hu Ming, deputy secretary-general of China Drilling Tools Association, gave a report on "Requirements and Expectations for the Use of Cemented Carbide for Mining in the Drilling Tool Industry". As one of the industries most closely related to the cemented carbide industry, Hu Ming, the deputy secretary-general of the China Brazing Steel and Drilling Tools Association, reported in detail the development status of the association and future technology and market trends, focusing on the cemented carbide industry in China. Some hope: the best design in terms of cemented carbide tooth profile, tooth crown shape, rock breaking speed, and increased wear volume to ensure greater strength and longer service life; according to drill bits, down-the-hole drill bits, Cone bits and other points that have a low rock breaking consumption rate and are difficult to recycle. In the product design and production process, reduce the use of cobalt as much as possible to reduce costs and prices; at the same time, it is hoped that China Tungsten Industry Association, Cemented Carbide Branch and related parties The company keeps close contact with the members of the association, and cooperates closely with the members of the association to expand the market and improve the technology. Finally, Deputy Secretary-General Hu also advises the cemented carbide industry to pay attention to superhard materials and coating technology in rock drilling. Cases of failure in rock breaking and poor cost-effectiveness.

CTIA‘s 2021 Tungsten & Cemented Carbide Development Research Annual Meeting, Shanghai